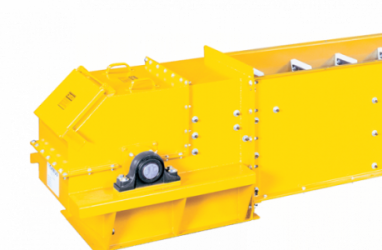

Tramco Model G - Sludge Version

En-Masse Conveyor provides years of trouble-free service under extreme applications. All wear parts are easy to replace making the conveyor very maintenance friendly. The MODEL G™ is frequently used in such industries as chemical, coal, food, grain, municipal solid waste, mining, plastic, paper, pulp and rubber.

The MODEL G™ has been put into service around world by some the world’s greatest companies.

Standard Model G™ Features

Standard Model G™ Features

- All conveyor sections are pre-assembled on a level 215ft fixtures, match-marked and dowel-pinned for field assembly. With proper rigging practices, Intermediate Sections can be assembled and shipped in multiples of up to 40 ft. lengths saving on field time.

- ~3 mils Powder Coat finish. The finish has a good hardness, excellent flexibility, excellent exterior stability, good chemical and solvent resistance, and a very good corrosion protection. All parts are powder coated before assembly. All fasteners are cadmium plated.

- Drives are pre-assembled with the oil bath chain case fitted and removed for shipment.

- Oil bath chain cases are split with two top inspection doors, one over each sprocket.

- All liners use 1/2″ welded studs attached to the exterior of the liner plates to eliminate wear points on the inside of the liners.

- Head and tail housing assemblies are split for easy access.

- Out-board mounted bearings on the head section.

- Rex ZT center pull take-up bearings on the tail section. Shaft seals are a Rino adjustable “packing-gland” split type.

- “G” style head sections come with a plug relief door and switch.

- All internal conveyor sprockets are split, with four lifting holes and hardened to ~420 BHN. Split sprockets can be “turned around” for double life. “Walking Tooth Sprockets” used where applicable.

- Conveyor chains are all cotter-constructed for ease of removal. All links are pre-heated prior to robotic welding of the attachment bars.

- Conveyor “By-Pass” inlets have a bolted side plate construction to ease removal/replacement of the internal liner plates without removal of the feed spout and or transition.

- All intermediate sections are pinned and robotically welded in fixtures to ensure squareness and length.

Designed to convey a wide variety of materials:

- Wet, Sticky and/or Oily Products

- Varying pH Conditions (Both High and Low)

- Changing Process Densities

- All Particle Sizes (Certain Limitations Apply)

- Varying Temperature Ranges

- Both Abrasive and Corrosive Products

- High Moisture Products

- Possible configurations:

- Horizontal Conveyor with multiple self-feeding inlets and multiple outlets

- Incline conveyor (up to 15 degrees) with multiple inlets and multiple outlets

- Curved conveyor with incline and multiple inlets